| Place of Origin: | Tianjin |

| Brand Name: | KDI |

| Model Number: | M1.25 |

| Certification: | ISO9001:2015/ CE |

| Minimum Order Quantity: | 10pcs |

| Packaging Details: | Small qty with cartoon box, large qty with wooden box |

| Delivery Time: | About 15 to 30days. |

| Payment Terms: | TT |

Precision Engineered for Motion: DIN7 M1.25 Helical Gear Rack for High-Performance CNC Laser Engraving

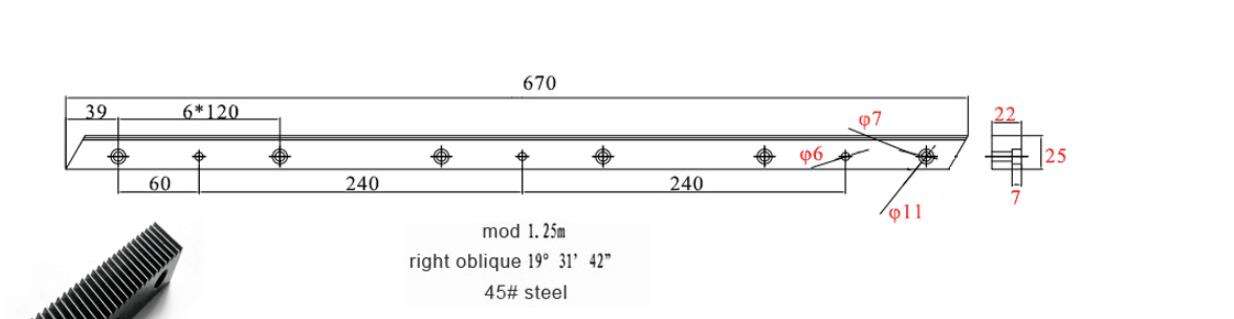

In the demanding world of precision manufacturing, the accuracy and smoothness of linear motion are paramount. Introducing our premium M1.25 Helical Gear Rack, meticulously engineered to meet the exacting standards of modern CNC laser engraving and cutting machinery. With specifications of 22mm width, 25mm height, and a 670mm length, and manufactured to DIN7 precision grade, this component is the definitive solution for builders and maintainers of high-end CNC systems seeking reliability, quiet operation, and exceptional positional accuracy.

This gear rack is designed for seamless integration and optimal performance:

Modulus (Pitch): M1.25.

This fine pitch is ideal for applications requiring high resolution and smooth motion transfer, perfectly suited for the precise movements of a laser engraving head.

Dimensions: 22mm (Width) x 25mm (Height) x 670mm (Length).

This robust cross-section provides excellent rigidity and load-bearing capacity, ensuring stability during high-speed operation.

Tooth Profile: Helical (Spiral) Teeth.

Unlike straight-cut gears, the helical design ensures multiple teeth are in contact at any given time. This results in significantly smoother, quieter, and stronger engagement with the matching pinion gear, drastically reducing vibration and noise—a critical advantage in precision engraving environments.

Accuracy Standard: DIN7 Grade.

This classification signifies a high level of manufacturing precision. It guarantees minimal cumulative pitch error over the entire length, which translates directly to the superior positioning accuracy and repeatability of your CNC machine.

Helical Angle: Engineered with a precise 19°31'42" right-hand spiral angle, optimizing the meshing action for efficient power transmission and smooth motion.

Quality begins with the foundation. This rack is crafted from high-grade 45# (1045) carbon steel, chosen for its excellent strength, good machinability, and consistent microstructure. To maximize durability and service life, the rack undergoes a specialized surface hardening treatment, such as case hardening or induction hardening. This process creates an extremely hard, wear-resistant surface on the tooth flanks (typically reaching HRC 45-50) while maintaining a tougher, more flexible core to withstand shock loads.

The manufacturing process employs precision hobbing or milling on advanced CNC machinery, ensuring each tooth's geometry is consistent and true to the DIN7 standard. The final product often features a protective black oxide surface finish, which provides mild corrosion resistance and a professional appearance.

Integrating this helical gear rack into your laser engraver's X or Y-axis drive system delivers tangible benefits:

1.Enhanced Engraving Quality

The smooth, low-vibration motion from the helical engagement minimizes machine chatter. This stability is crucial for achieving clean, sharp edges and fine detail in engraving and cutting operations, especially at high speeds.

2.Quieter Operation

The gradual tooth engagement characteristic of helical gears dramatically reduces operational noise compared to straight-cut racks, contributing to a more pleasant and professional workshop environment.

3.Increased Load Capacity and Longevity

The larger contact area and robust steel construction allow the system to handle higher dynamic loads. The hardened tooth surface ensures exceptional resistance to wear, extending maintenance intervals and the overall lifespan of the drive system.

4.Improved System Rigidity

The solid 22x25mm profile acts as a sturdy linear guide, enhancing the machine's overall structural rigidity against cutting forces and inertial loads.

While its design is optimized for CNC laser engraving and cutting machines, this versatile precision component is equally effective in a wide range of automation and industrial machinery:

CNC Router Machines for woodworking, plastic, and composite material processing.

High-Precision Linear Motion Systems in automated assembly lines, pick-and-place robots, and material handling equipment.

Other CNC Machine Tools including milling machines, lathes, and plasma cutters where precise linear positioning is required.

This M1.25 x 22x25x670mm DIN7 Helical Rack is available as a standard item for quick delivery. We stand behind our product with a comprehensive warranty and support the confidence of our clients by providing mechanical test reports and factory inspection videos upon request.

For projects with unique requirements, we offer extensive OEM and ODM services. Our manufacturing capabilities allow for customization in material (including stainless steel), length, helical angle, and specific hardening protocols to meet your exact engineering drawings and application demands.

Elevate the performance of your precision machinery. Choose the helical gear rack that combines advanced engineering, superior materials, and certified accuracy. Contact our technical sales team today to discuss your specifications, request a sample, or place your order for reliable, high-performance linear motion solutions.