| Place of Origin: | Tianjin |

| Brand Name: | KDI |

| Model Number: | M0.5-M12 |

| Certification: | CE/ISO9001: 2015 |

| Minimum Order Quantity: | 10pcs |

| Packaging Details: | Carton box/Wooden box |

| Delivery Time: | 15 days. |

| Payment Terms: | TT |

Powering the Future: The Strategic Application of Worm Gears in Industrial Gearboxes

1.1.1 1. The Core Philosophy of Worm Gearing

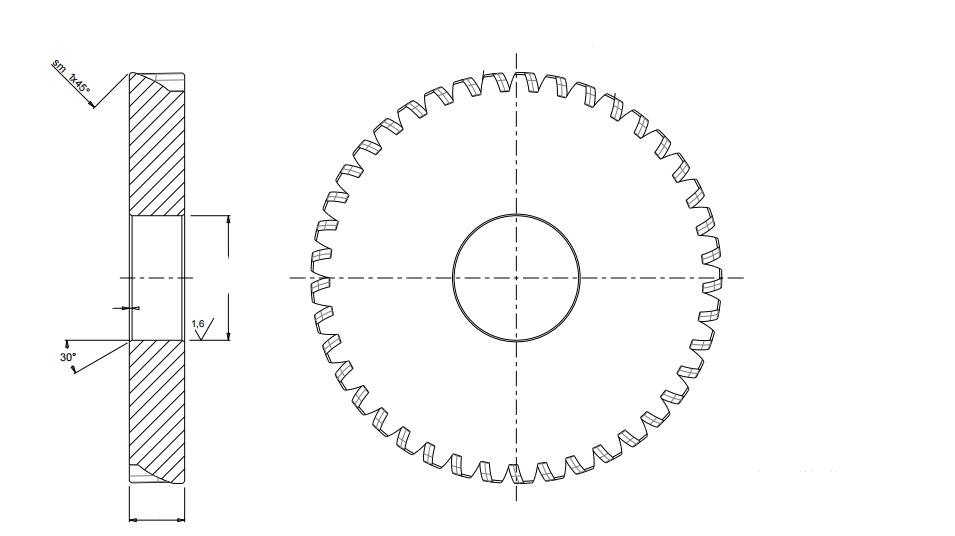

In the complex world of power transmission, the worm gear set stands out as a unique and indispensable solution. Comprised of a worm (a screw-like input shaft) and a worm wheel (a gear with specialized teeth), this configuration operates on a sliding contact principle rather than the rolling contact found in spur gears.

With 20 years of manufacturing excellence, our factory has observed that the true value of a worm gear lies in its ability to manage high reduction ratios in the most compact spaces while maintaining an exceptionally quiet operational profile.

1.1.2 2. Key Advantages in Gearbox Design

Why do engineers consistently choose worm gears for their gearbox designs? The reasons are rooted in three primary technical benefits:

A. Extreme Speed Reduction in a Single Stage

Unlike helical or spur gears, which typically require multiple stages to achieve high ratios, a worm gear set can achieve ratios from 5:1 to 100:1 (and even higher in specialized cases) in a single pass. This significantly reduces the size and weight of the gearbox housing.

B. The Self-Locking Phenomenon

One of the most critical safety features of worm gearing is its potential for self-locking. When the lead angle of the worm is small enough, the gear cannot drive the worm. This is a game-changer for lifting equipment, elevators, and conveyors, acting as a secondary fail-safe against back-driving.

C. Noise Attenuation and Vibration Dampening

The sliding action between the worm and the gear teeth naturally dampens vibrations. This makes worm gearboxes the preferred choice for environments where noise pollution must be minimized, such as theater stage equipment, medical devices, and residential elevators.

1.1.3 3. Material Science and Durability

Twenty years of production experience have taught us that the secret to a long-lasting worm gearbox is the material pairing. To minimize the friction inherent in sliding contact, we utilize a "soft and hard" pairing strategy:

The Worm: Typically crafted from high-alloy steel (like 20CrMnTi or 42CrMo), case-hardened to HRC 58-62 and precision-ground to a mirror finish.

The Worm Wheel: Cast from premium Tin Bronze (e.g., ZCuSn10P1) or Aluminum Bronze. Bronze provides natural lubricity and wear resistance, "sacrificing" itself slightly over time to protect the worm.

1.1.4 4. Critical Applications Across Industries

Our precision-engineered worm gear sets are currently driving innovation in several key sectors:

Material Handling & Logistics: Automated warehouses rely on worm gearboxes for conveyor belts and sorting systems where constant torque and frequent starts/stops are required.

Solar Tracking Systems: The high reduction ratio and self-locking capabilities are perfect for precisely positioning solar panels to follow the sun’s path, resisting high wind loads without moving.

Heavy Duty Winches: In mining and marine applications, the ability to hold a load in place without constant motor power is a vital safety and efficiency feature.

Food and Beverage Packaging: The compact right-angle orientation allows these gearboxes to fit into the tight confines of bottling and labeling machines.

1.1.5 5. Overcoming Challenges: The Importance of Lubrication and Thermal Management

While worm gears are highly efficient in terms of space, the sliding contact generates more heat than other gear types. As a manufacturer with two decades of expertise, we emphasize:

Precision Grinding: Reducing surface roughness to minimize friction.

Synthetic Lubricants: Recommending high-quality PAG (Polyalkylene Glycol) oils to handle the thermal load.

Advanced Housing Design: Utilizing finned aluminum or cast-iron housings to optimize heat dissipation.

1.1.6 6. The 20-Year Manufacturer’s Promise

In the transmission industry, there is no substitute for experience. Over the past 20 years, we have refined our contact pattern analysis and heat treatment protocols to ensure that every gear set we produce offers maximum efficiency and a service life that exceeds industry standards.

We don't just manufacture parts; we provide the mechanical heart of your machinery. From custom tooth profiles to specialized coatings, our engineering team is ready to optimize your gearbox performance.

Would you like me to expand on the specific maintenance protocols for these gearboxes, or perhaps provide more technical details on the "self-locking" calculations?