| Place of Origin: | Tianjin |

| Brand Name: | KDI |

| Model Number: | M0.5-M12 |

| Certification: | CE/ISO9001: 2015 |

| Minimum Order Quantity: | 1000pcs |

| Packaging Details: | wooden cases |

| Delivery Time: | 15 days. |

| Payment Terms: | TT |

High-Performance Industrial Worm Gears & Worm Shafts: 20 Years of Precision Engineering

1.1.1 1. Introduction: The Pinnacle of Power Transmission

At the heart of modern industrial automation lies the need for smooth, quiet, and high-torque power transmission. With over two decades of specialized manufacturing experience, our factory has perfected the art of producing high-precision Worm Gears and Worm Shafts.

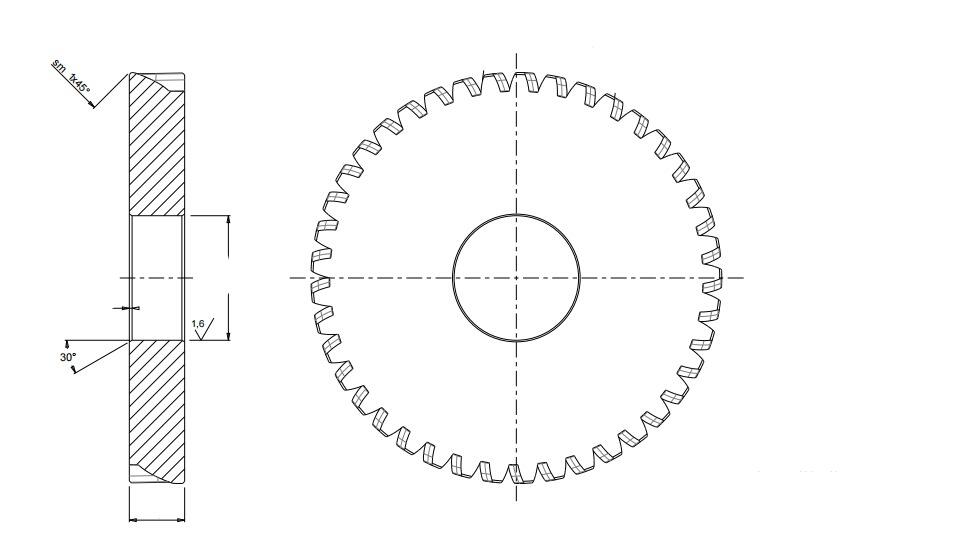

Worm gearing is a unique solution where a worm (a gear in the form of a screw) meshes with a worm gear (similar in appearance to a spur gear). This configuration allows for high reduction ratios in a compact space, making it an indispensable component in heavy-duty machinery.

1.1.2 2. Why Choose Our Worm Gear Systems?

Our 20-year journey in the transmission industry has taught us that reliability is non-negotiable. Our products are engineered to provide:

High Reduction Ratios: Achieve significant speed reduction and torque multiplication within a single stage.

Self-Locking Capability: Depending on the lead angle, our worm gears can act as a natural brake, preventing back-driving and enhancing safety in lifting applications.

Quiet and Smooth Operation: The sliding contact nature of worm gearing results in significantly lower noise levels compared to spur or helical gears.

Space Efficiency: The right-angle configuration allows for compact gearbox designs, ideal for tight industrial footprints.

1.1.3 3. Material Excellence & Technical Specifications

A gear is only as good as the material it is made from. We utilize a combination of premium alloys to ensure a balance between strength and friction reduction.

| Component | Standard Material Options | Treatment |

| Worm Shaft | 20CrMnTi, 40Cr, 42CrMo Steel | Case Hardening (HRC 58-62), Nitriding |

| Worm Wheel | ZCuSn10P1 (Tin Bronze), Aluminum Bronze, Nylon | Centrifugal Casting for high density |

1.1.1 4. Advanced Manufacturing Process

Our factory utilizes a vertically integrated production line. Having managed our own facility for 20 years, we have optimized every step:

Precision Forging: We start with high-density blanks to eliminate internal voids.

CNC Worm Grinding: We use state-of-the-art Reishauer or similar high-precision grinding machines to ensure the worm profile is perfect, reducing friction and heat.

Hobbing & Centrifugal Casting: Our worm wheels are produced using centrifugal casting for bronze rings, ensuring a grain structure that resists wear better than standard sand casting.

Heat Treatment: Our in-house heat treatment facility allows for precise control over the case depth and hardness of the worm threads.

1.1.2 5. Rigorous Quality Control (QC)

"Quality is the lifeblood of a factory." Every gear set that leaves our facility undergoes a multi-stage inspection process.

Coordinate Measuring Machine (CMM): To verify complex geometries and lead accuracy.

Contact Pattern Testing: We perform "blueing" tests to ensure the contact area between the worm and gear is centered and optimized for load distribution.

Hardness Testing: Verification of the Rockwell or Vickers hardness to guarantee long-term wear resistance.

Surface Roughness Analysis: Ensuring the worm thread surface is mirror-finished to minimize the coefficient of friction.

| Module Range: | 0.5 – 25 Mod |

| Accuracy Grade: | DIN 5 to DIN 9 / AGMA 10-12 |

| Pressure Angle: | 14.5°, 20°, or customized per client blueprints. |

| Structure: | Solid wheel, bolted ring, or composite casting. |

Our transmission components are trusted by engineers worldwide across various sectors:

Lifting & Elevators: Utilizing the self-locking feature for safety.

Conveyor Systems: For steady, high-torque movement in mining and logistics.

Packaging Machinery: Precise indexing and speed control.

Renewable Energy: Solar tracking systems that require high precision and weather resistance.

Agitators & Mixers: Handling high shock loads in chemical processing.

Working directly with an experienced manufacturer like us offers benefits that trading companies cannot match:

OEM & ODM Services: We can manufacture based on your samples, drawings, or even a simple concept.

Technical Consultation: Our engineering team can help you optimize gear geometry to increase service life or reduce noise.

Cost Efficiency: By eliminating the middleman and optimizing our 20-year-old supply chain, we offer premium quality at competitive pricing.

Fast Prototyping: We understand the urgency of R&D and offer rapid turnaround for custom gear sets.

Whether you are designing a new robotic arm or maintaining a heavy-duty industrial crane, our worm gears provide the reliability your project deserves. With two decades of expertise, we don't just sell gears; we provide transmission solutions that move the world.

Inquiry Notice: To provide a precise quote, please specify the Module, Number of Teeth, Material requirements, and any specific heat treatment needs.