| Place of Origin: | Tianjin |

| Brand Name: | KDI |

| Model Number: | OEM |

| Certification: | ISO9001:2015/CE |

| Minimum Order Quantity: | 10pcs |

| Packaging Details: | Wooden box |

| Delivery Time: | Depend on type and quantity |

| Payment Terms: | TT |

Hydrostatic worm gear and rack systems

Hydrostatic worm gear and rack systems (often referred to as hydrostatic worm rack drives) are high-precision linear motion systems used primarily in large-scale, heavy-duty machine tools. Unlike traditional mechanical systems where metal teeth touch, these systems use a pressurized oil film to separate components, virtually eliminating friction and wear.

Working Principle & Design The system consists of a worm (threaded screw) and a rack (internally threaded or toothed member). The "hydrostatic" element comes from specialized oil pockets integrated into the teeth of the worm or the rack.

Oil Film Separation: High-pressure oil is pumped into these pockets, creating a consistent thin film (hydrostatic bearing) between the worm threads and rack teeth. This ensures there is no metal-to-metal contact during operation.

Constant Mesh: The worm rotates against the rack, and the pressurized oil transmits the force, converting rotational motion into smooth, high-torque linear motion.

Axial Control: The axial position of the worm is often fixed by additional hydrostatic thrust bearings to handle high axial loads without backlash.

Extreme Precision: Because the oil film dampens vibrations and compensates for minor geometric errors, these drives offer exceptional positioning accuracy over long distances (often >10 meters) .

Zero Wear: No physical contact means the components do not wear down over time, maintaining "as-new" precision for decades.

High Rigidity: The oil film provides high dynamic and static stiffness, which is critical for maintaining accuracy under heavy cutting loads.

Smooth Motion: They eliminate "stick-slip" effects common in mechanical drives, allowing for extremely smooth movement even at very low speeds.

Major Applications

These systems are reserved for high-end industrial machinery where standard rack and pinion or ball screws lack sufficient load capacity or accuracy.

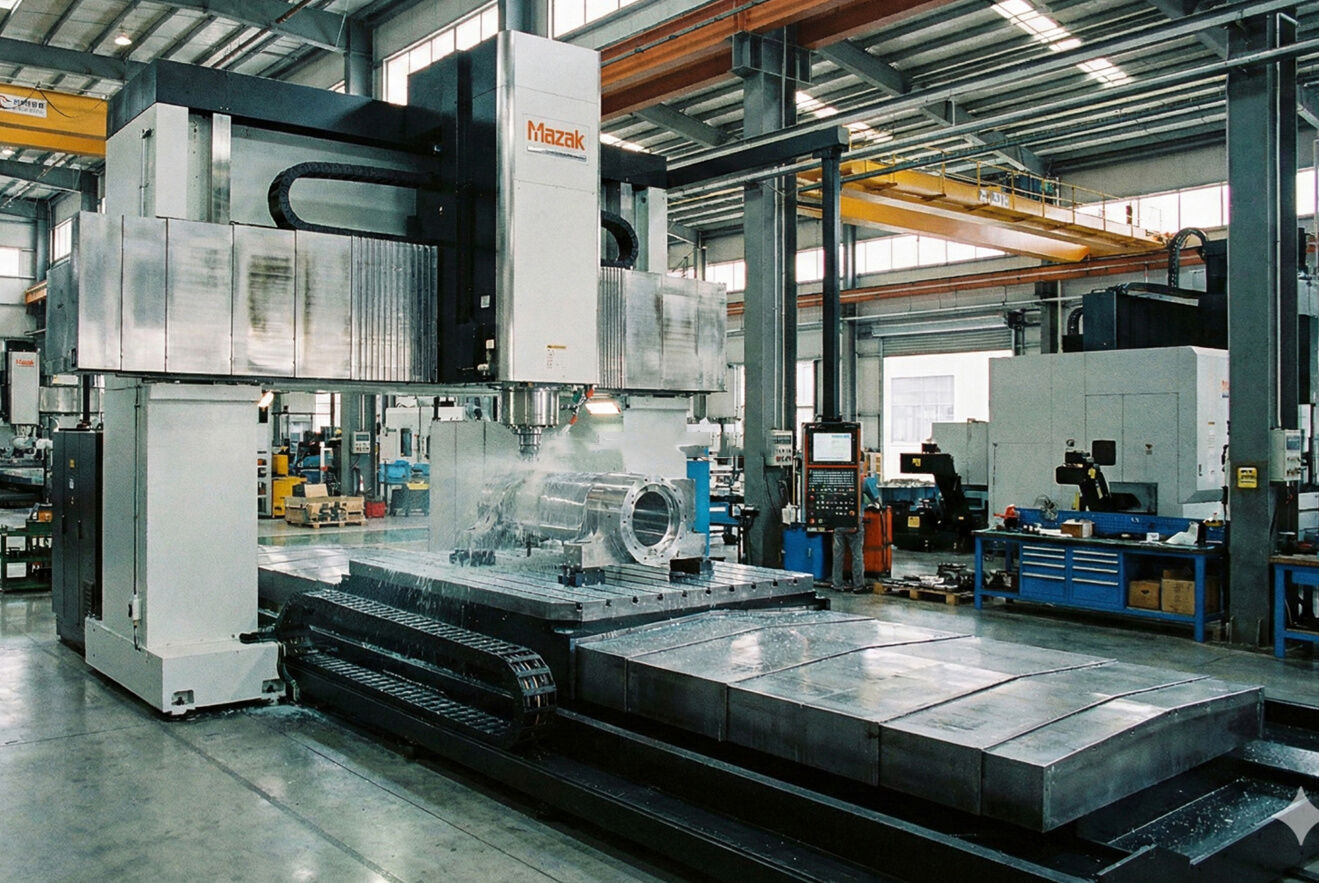

Machine Tools: Used in the X-axes of large portal milling machines, boring mills, and grinding machines (e.g., travel lengths exceeding 14,000 mm).

Processing

1. Milling Process

It is the most basic worm rack processing technology, divided into two types: disc milling cutter milling and finger milling cutter milling.

2. Shaping Process

Using a gear shaper cutter to process the worm rack tooth profile by the generating method, which can process straight-tooth and helical-tooth worm racks.

3. Hobbing Process

Using a special worm rack hob, continuous cutting according to the generating principle, it is one of the processes with the highest efficiency and precision at present.

4. Grinding Process

Test & Report

Inspection steps before delivery: Use GO/Nogo inspect hole---Use micrometer check dimensions---Next use stiffness detection system inspect hardness--Finally use CMM inspect precision.

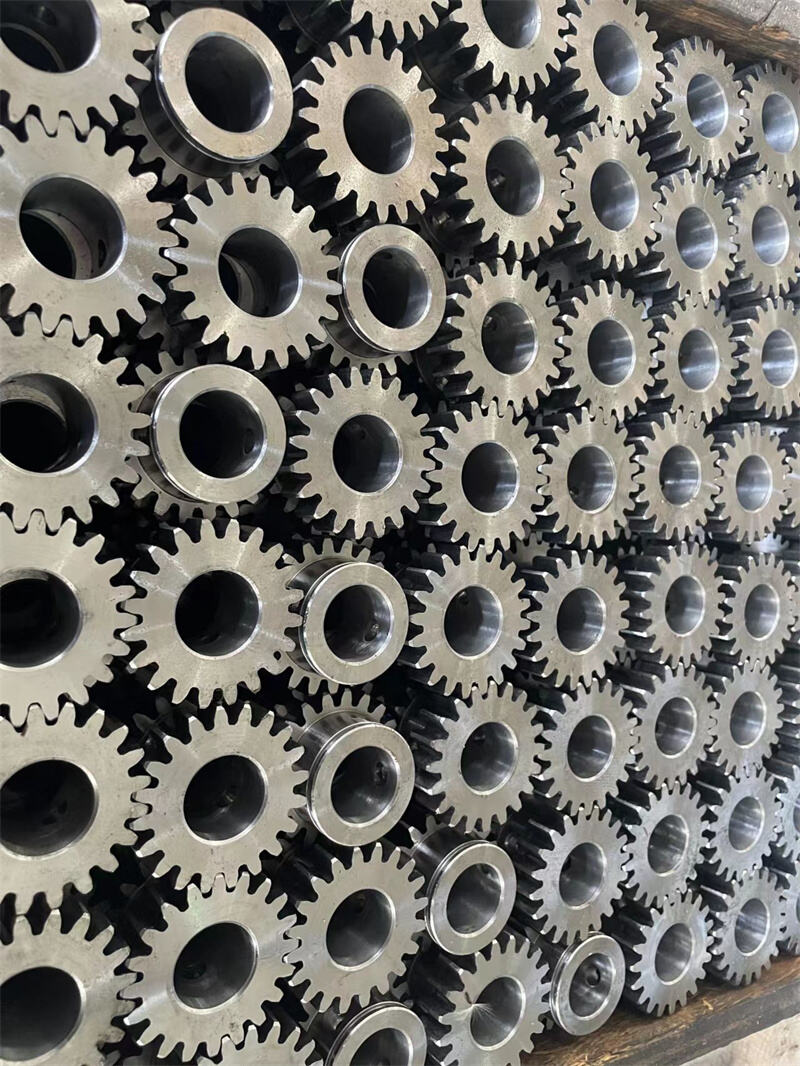

Before process, we will provide drawing according to customers' drawing and requirements. During process, we will produce the pinion gears totally according to the drawings. After finish, we will test the pinion gears carefully according to the drawings. We can also provide material report, accuracy report, shape report, hardness report if customer need.

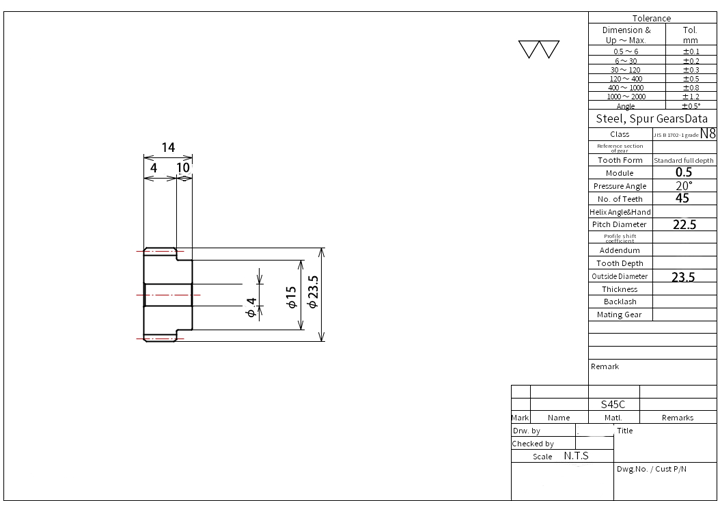

Gear Drawing

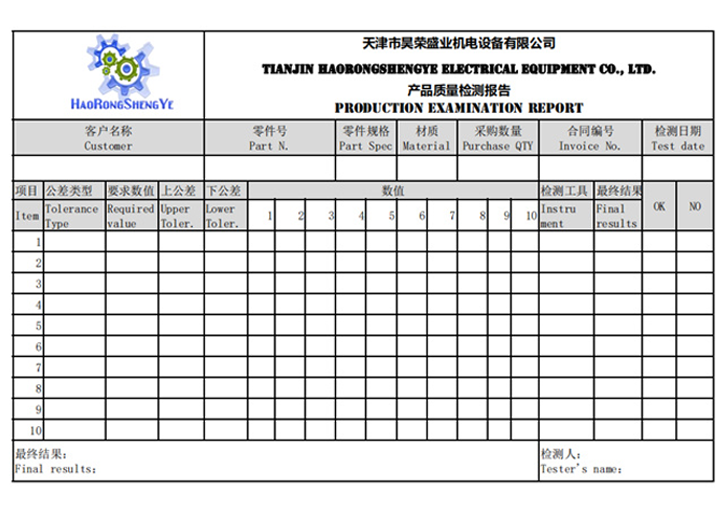

Dimension Report

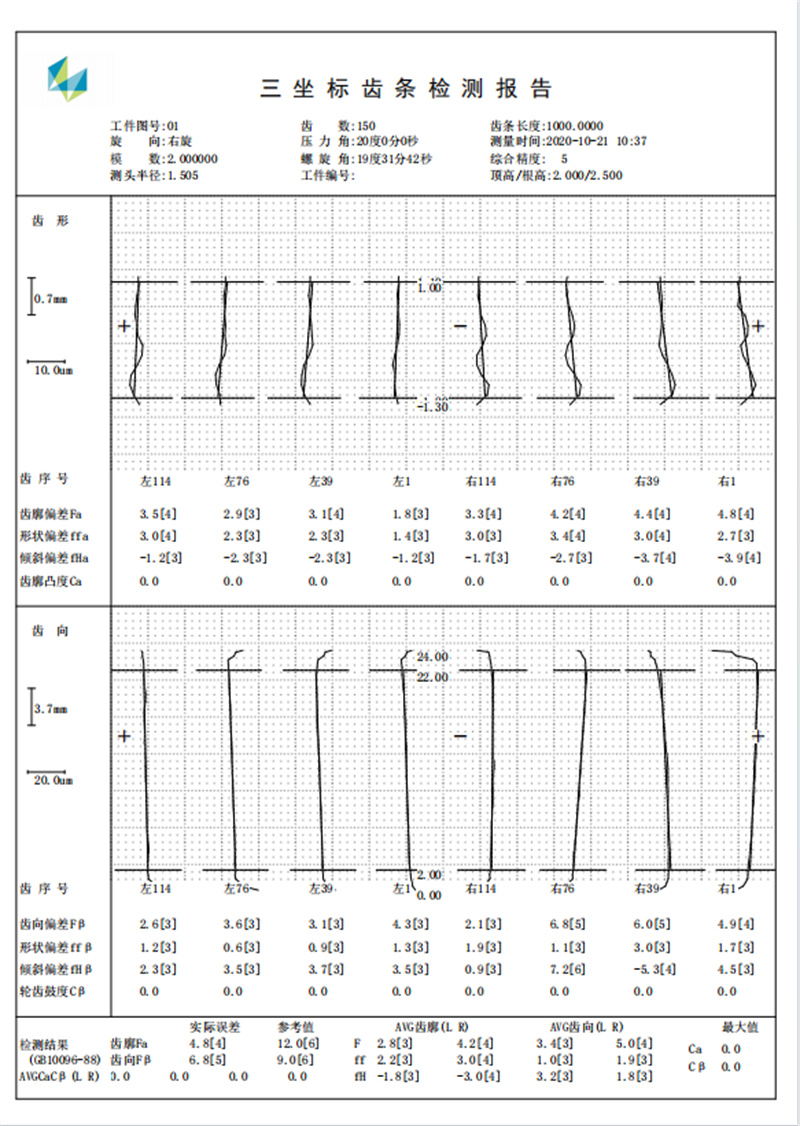

Accuracy Report

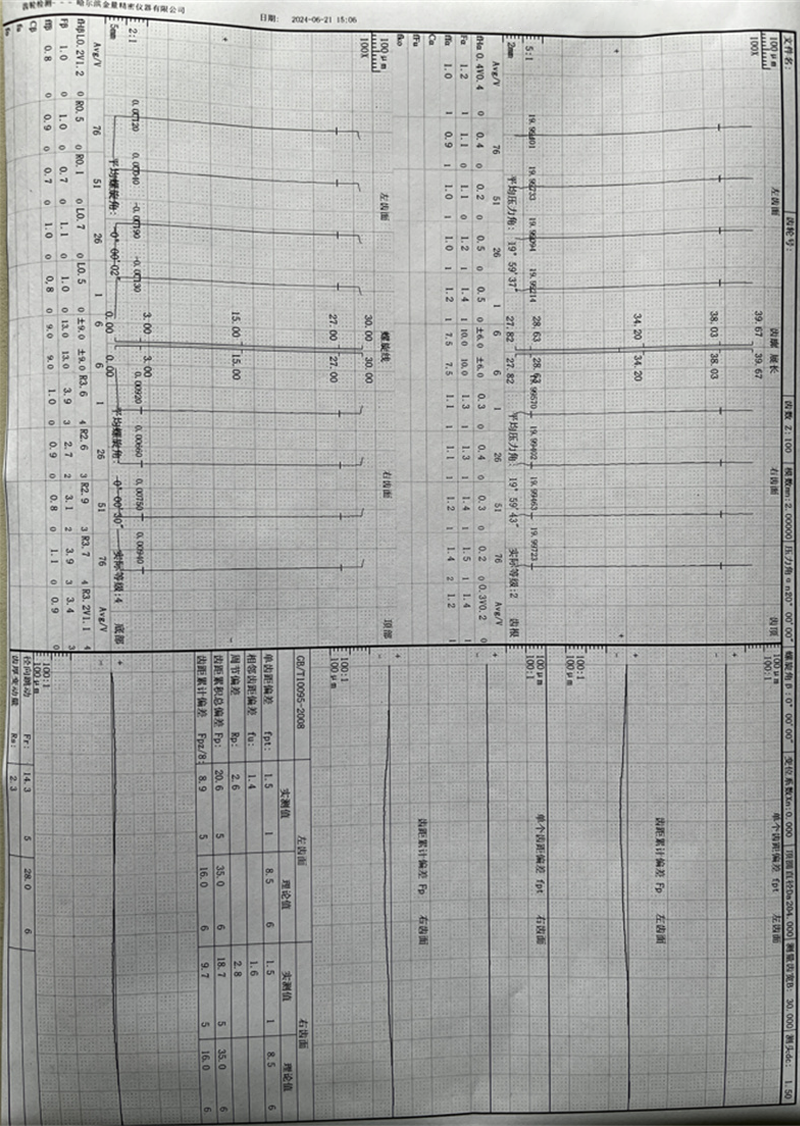

Shape Report

Tianjin Haorongshengye is strictly adhere to CE certificate standard and ISO9001 certificate standard.

We will always focus on quality!

Our workshop will package the gears carefully with cartoon box first, for large quantity, we will put the gears into wooden box and do the anti-water.

Small quantity: We will use carton box.

Big quantity: We will use wooden case.

Tianjin Haorongshengye gears can be used on Precision cutting machines.Lathes machine, Milling machines, Grinders machine, Automated mechanical systems, Automated warehousing systems.

These systems are reserved for high-end industrial machinery where standard rack and pinion or ball screws lack sufficient load capacity or accuracy. Machine Tools: Used in the X-axes of large portal milling machines, boring mills, and grinding machines (e.g., travel lengths exceeding 14,000 mm).

To get what you want:

1. About us

Our factory is established in 2008 and located in Tianjin, near Beijing. We have more than 20years manufacturing experience and 15 years export experience.

2. Our main products

We are focus on power transmission parts, including standard and OEM high precision gear, gear rack, sprocket, roller chain, timing pulley, timing belt and other mechanical transmission products.

3. Certifications

We strictly adhere to the ISO 9001 quality management system and international CE certification standards to ensure products meet customer requirements.

4. Can l obtain samples?

Yes.

5.Can l use my own nameplate on the product?

Yes, if you need, please communicate in advance.

6. When will the shipment be made?

The general standard type delivery time is 7 to 15 days. lf the quantity is large, we will communicate with you in advance based on the actual situation.

7.How to place an order?

Just tell us what you need, then we can make a Invoice for you. If all OK , then make the order and we shipping to you the goods ASAP. In order to ensure that all products are what you need, we will show you the pictures, drawings, videos and so on before shipping .

8. What's the payment term?

We normally accept T/T, Western Union, L/C, and Paypal.