| Place of Origin: | Tianjin |

| Brand Name: | KDI |

| Model Number: | M2 |

| Certification: | CE/ISO9001: 2015 |

| Minimum Order Quantity: | 1000pcs |

| Packaging Details: | wooden cases |

| Delivery Time: | 15 days. |

| Payment Terms: | TT |

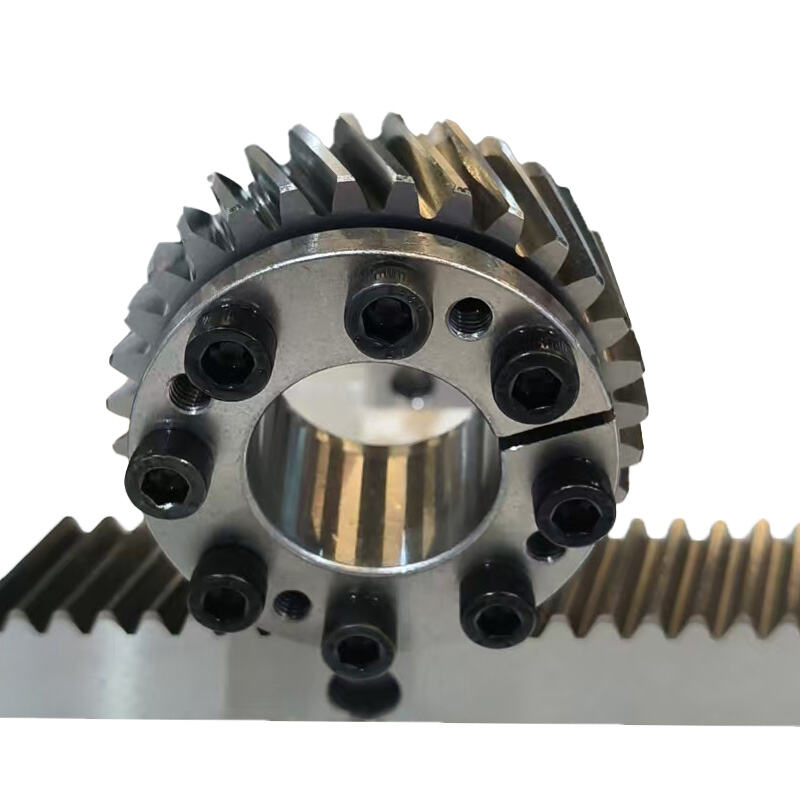

High-Precision Helical/Spur Gear Rack and Pinion Systems for Industrial Woodworking CNC Machinery

Engineered for High-Speed Cutting, Superior Positioning Accuracy, and Long-Term Durability in Dust-Intensive Environments.

Professional Overview

In the high-speed woodworking industry, transmission components must balance dynamic response with extreme precision. Our gear racks are specifically engineered for the rigorous demands of CNC routers, edge banders, and panel saws. By utilizing advanced heat treatment and precision grinding, we ensure minimal backlash and maximum feed force, even under continuous 24/7 heavy-duty operation.

Use this structured table to demonstrate technical rigor.

| Feature | Technical Data / Options |

| Module (M) | M1, M1.25, M1.5, M2, M3, M4, M5, M8 |

| Tooth Type | Helical (Left/Right Hand 19°31'42") or Straight Spur |

| Pressure Angle | 20° |

| Precision Grade | DIN 6h25, DIN 7h25, DIN 8h25, DIN 10 |

| Material Grades | C45 (S45C), 40Cr, 20CrMnTi, Stainless Steel |

| Hardness Treatment | Induction Hardened (HRC 45-55) or Quenched & Tempered |

| Total Pitch Error | Up to $\le 0.022 \text{ mm} / 1000 \text{ mm}$ (for DIN 6) |

| Standard Lengths | 500mm, 1000mm, 2000mm (Continuous mounting support) |

Key Technical Advantages for Woodworking To stand out, highlight the engineering logic behind your manufacturing:

A. Optimized Helical Tooth Geometry Our 19°31' 42" helical angle increases the Contact Ratio compared to straight teeth. This results in: Lower Noise Levels: Essential for high-speed CNC environments. Smoother Motion: Eliminates vibration marks on the finished wood surface. Higher Load Capacity: Distributes stress over a larger surface area.

B. Specialized Surface Metallurgy Woodworking produces fine abrasive dust. Our racks undergo Surface Induction Hardening, creating a hard outer shell (HRC 50+) to resist wear, while maintaining a tough, flexible core to absorb structural shocks during rapid direction changes.

C. Precision Grinding & Parallelism

D. We utilize high-precision CNC rack grinding machines. Every meter of our DIN 6 rack is inspected for Pitch Deviation and Parallelism, ensuring that the gantry moves with zero "stick-slip" effect, which is critical for intricate carving and 3D milling.

Show that you understand their machine architecture. CNC Routers (Nested Base Manufacturing): High-speed X and Y-axis transmission for rapid traversing. Edge Banding Machines: Precise synchronization of the feed chain and trimming units. Beam Saws / Panel Saws: Heavy-duty positioning for high-volume board cutting. Multi-Spindle Boring Machines: Accurate center-to-center hole placement.

Quality Assurance (The "Trust" Factor)We don't just manufacture; we validate. Each shipment can be provided with:Material Certificate: (Chemical composition analysis). Hardness Test Report: Ensuring depth and consistency of heat treatment. Lead Error Inspection: Full-length accuracy verification.

Customization & OEM Services As a direct factory, we support specialized requirements:

Custom Bolt Hole Patterns: Pre-drilled to match your machine frame.

End-Face Machining: For seamless continuous joining (unlimited travel length).

Matching Pinions: We provide ground pinions with integrated shafts or keyways for a complete "Plug-and-Play" solution.

Suggested Next Step:

Would you like me to draft a "Request a Quote" (RFQ) form for this page? This will help you filter high-quality leads by asking customers for specific technical requirements like Module, Length, and Precision Grade.

Installation:

To assemble connected racks more smoothly, 2 ends of a standard rack would add half tooth which is convenient for next half tooth of next rack to be connected to a complete tooth. The following drawing shows how 2 racks connect and tooth gauge can control pitch position accurately.

With regards to connection of helical racks, it can be connected accurately by opposite tooth gauge.

1. When connecting racks, we recommend lock bores on the sides of rack first, and lock bores by the sequence of the foundation. With assembling the tooth gauge, pitch position of racks can be assembled accurately and completely.

2. Last, lock the position pins on 2 sides of rack; the assembly is completed.

Our Product Advantages for Woodworking Machinery

1.Superior Dynamic Stability

Engineered for high-frequency direction changes and rapid traversing. Our helical systems provide a high contact ratio, ensuring smooth, vibration-free operation even at feed speeds exceeding $60m/min$.

2. Exceptional Wear & Dust Resistance

Featuring specialized surface hardening (HRC 50-55), our racks resist abrasive wear caused by fine wood dust and debris, significantly extending maintenance intervals.

3. Precision Positioning

With precision grades up to DIN 6, we control total pitch error within microns, ensuring dimensional consistency for large-format panel cutting and intricate 3D carving.

Why Choose Us - Our Core Strengths

1. Industry-Specific Expertise

With decades of experience in power transmission, we deeply understand the rigorous demands of the woodworking industry—from edge banders to 5-axis machining centers.

2. Fully Integrated Manufacturing

From raw material sourcing and precision milling to heat treatment and CNC grinding, every process is handled in-house, ensuring a closed-loop, traceable quality control system.

3. Advanced Customization Capabilities

We go beyond standard modules. We offer tailored solutions, including non-standard lengths for seamless joining, custom bolt-hole patterns, and specific tooth geometries to fit your unique machine design.

4. Rigorous Quality Assurance

Every shipment is accompanied by material and precision inspection reports. We utilize advanced metrology tools, including laser interferometers and hardness testers, to guarantee zero-defect delivery.